Over the past five decades, the advantages of the Taiwan printed circuit board (PCB) industry lay in its complete and centralized supply chain, quality control, and the cross Strait relations. The industry has held 30% market share of the global PCB markets since 2010. Thanks to the rapid development of high-end mobile phones in recent years, the 2017 industrial value of overall PCB industrial supply chain at both sides of the Strait surpassed $30 billion, creating a historical level high.

The PCB industry is one of the most competitive industries in Taiwan, while Automated Optical Inspection (AOI) equipment is vital to improving production capacity of PCBs and the yield rate of products. AOI equipment can be placed in the middle of production lines to inspect semifinished products without affecting production capacity. As a result, AOI equipment is an important investment in the PCB manufacturing process with a comparatively high proportion- about 15% of the total investment amount.

Difficulties and challenges

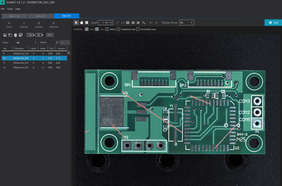

AOI is an automated visual inspection that scans the surface of a PCB to acquire a clear image. Then depending on computer image processing technology, AOI equipment can check if defects such as short circuits, excessive or insufficient copper, open circuits, nicks, burrs, copper slags, missing components, and deflections exist. As a variety of surface defects exist, the inspection is more difficult compared with that of general electronic components.

Currently, AOI inspection is confronted with a phenomenon of overkill. Due to the extremely high yield rate requirement of PCBs, the design parameters of AOI equipment is very strict. As a result, overkill occurs in AOI due to the over sensitiveness of equipment. According to statistics, the overkill rate is as high as 70%, which means 70% of semi-finished goods are qualified. Due to a high overkill rate, a second manual screening must occur to differentiate between real defects and false-positives before they return to the product line.

G4 Technology’s Artificial Intelligence (AI) Defect Inspection System

G4 Technology Co., Ltd in Taiwan has been committed to providing imaging solutions for machine vision and AOI as well as services for enterprises’ successful application of machine vision technology. The company has strictly controlled quality in manufacturing not only to improve the yield rate of products and production efficiency, but also to effectively reduce inspection costs. Recently, G4 Technology launched their AI defect inspection system demo. This system can capture images using an Allied Vision Manta G-032C industrial camera, a Fuji film high resolution lens, and SUALAB’s SuaKIT AI visual inspection software with the latest deep learning algorithm to inspect, detect, mark, and classify PCB defects in real-time.

The deep learning technology released by SUALAB utilizes an artificial neural network to analyze PCB images. Compared with traditional visual technology, this defect inspection system can analyze complex images, significantly improve image interpretation skill and accuracy of automatic visual inspection, and conduct automatic classification of defects. The required image data in the initial stage of deep learning algorithm varies with different complexity of images. Generally, 50 to 100 images are needed, which means this system can easily handle customer-specific defect standards.

Manta Camera helps in PCB inspection accuracy and stability

The Manta G-032C camera equipped in the G4 Technology AI defect inspection system, is a high-quality industrial camera with 656×492 resolution (0.3 megapixels). Its 80 frames per second is enough to meet normal demand. Generally, a model of corresponding neural network is established after 15 minutes. After which, 80 images per second can be collected and processed in real-time on a production line.

“When we selected the Manta camera for this PCB inspection demo, we mainly considered the high-speed requirement of the environment for real-time inspection, which required us to transfer images quickly with comparatively small-sized images. This type of camera has a comparatively high frame rate to meet the requirement of inspection speed,” said Ken Chou, the General Manager of G4 Technology, “In addition, Allied Vision cameras are the best match with the AI inspection algorithm due to its German quality and stability. Actually, according to different applications, almost all Allied Vision camera series can be regarded as ideal choices for PCB inspection. For example, if customers have high requirement on inspected image quality, an Allied Vision high resolution camera series such as Prosilica GT can be utilized.”

The Manta is Allied Vision’s most versatile GigE vision camera series. Numerous modular options, including angled head and board level versions, facilitate the camera integration in almost any application. The advanced feature set of the Manta, including multi-camera synchronization, user’s instruction and Ethernet trigger function, simplifies the setup of multi-camera applications and enables to reduce the overall cabling efforts and costs.

![]()