Prakash Prabhu – Chief Business Officer & Co-Founder, VisionBot

In this feature, we will together discover the basic concept of Augmented Computer Vision, it’s use in the real world to automation of tasks, turn images and video in to strategic information, and build exception based alert reporting. We will also consider industry use cases and what we should consider when implementing AI/ ML driven visual content monitoring applications in any organization.

Augmented Computer

Vision To augment means to improve, enhance something and get more specific and detailed information. The goal is to use artificial intelligence and machine learning to derive enriched cognitive information from computer vision video data also known as cognitive augmentation or Augmented Computer Vision.

Purpose

Augmented Computer Vision focuses on using artificial intelligence (AI/ ML) tools in an assistive role to enhance the partnership between human and artificial intelligence to enhance cognitive performance for better visual content monitoring and inspection application.

Technology

System delivering augmentation use artificial intelligence technologies to complement human output. Augmented AI uses technologies such as:

- Machine learning: Systems learn from data to identify patterns and create a feedback loop to learn and improve.

- Logical reasoning: This uses logical techniques to rationalize and assist in conclusions and deductions based on available data to solve problems and make predictions.

- Spatial navigation: They are designed to work with temporal and spatial information.

- Machine vision: This enables a computer to see for automatic analysis and inspection.

- Pattern recognition: This is automated recognition of patterns within data by spotting regularities or irregularities.

Functions

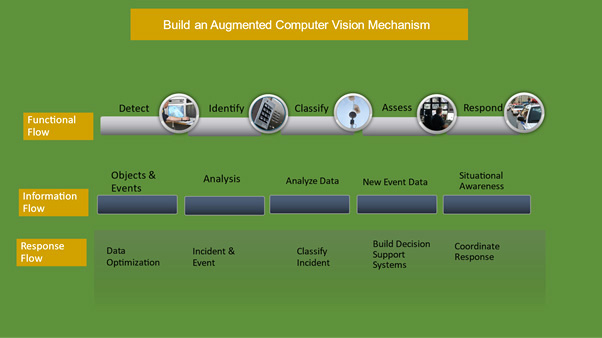

Augmented Computer Vision employs five main functions:

- Detect: Video data is fed to the system; detection & classification is then derived from.

- Identify: As new data is input, the old data is analysed, and new data sets are identified.

- Classify: The new data set then defines results.

- Assess: Humans then provide feedback on the results or output, and the system is adjusted.

- Respond: Defined processes are used to ensure compliance and security for risk management.

Augmented Computer Vision can

- Enhance operational decision-making.

- Save time by sorting through high volumes of Video data.

- Drive profits and reduce risks by successfully predicting patterns.

- Remove human error and bias in data interpretation.

- Allow operators to make more accurate data-driven decisions in real time.

Augmented Computer Vision is meant to in crease the intelligence of both, the computer and the human user. When used properly in tandem, man and machine can be smarter together. AI and augmented data from Visual Content Monitoring can open the door for more creativity and new innovations by assisting and enhancing human capabilities.

Application of Augmented Computer Vision

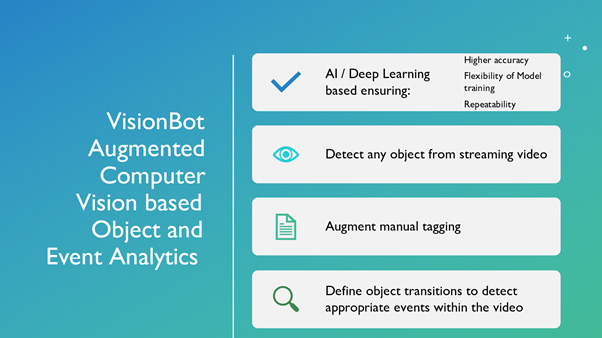

The spectacular development of Deep Learning approaches, has revolutionized video analysis and its applications.

Computer Vision techniques have moved from classic use cases (e.g., Triggering an alert if the camera image gets too dark or changes drastically) and has since moved to systems capable of identifying specific objects in an image and tracking their path.

Augmented Computer vision is proving to be a game-changer, with a plethora of applications in Visual Content Monitoring and Visual Inspection Monitoring applications in virtually every industry, allowing it to leverage the power of deep learning and, as a result, provide faster, cheaper, and superior automation. Primary use case would be for Automated Visual Inspection (AVI).

Areas of Requirement

It is that is required in both continuous and discrete operational scenarios. In non-production contexts, a visual inspection can be used to evaluate whether the traits indicative of an ‘object or behaviour’ are present and prevent possible negative consequences, similar to how it is used in manufacturing for quality or defect evaluation. There are numerous other industries where visual inspection is used and till now is done manually as it was considered a high-risk area.

How Automated Visual Inspection using Augmented Computer Vision is better than Manual Inspection

- Automatic image correction.

- Higher processing speed.

- Remote operations.

- Wider spectrum coverage.

- Higher accuracy.

- Zero fatigue.

- Scalable.

- Self-learning ability.

- Use past data for automated learning.

- Accurate model predictions.

Real World Industry Applications

- Construction

- Manufacturing

- Warehousing & logistics.

- Warehousing & logistics.

- Healthcare

- Retail

- Food & hospitality.

- Smart & safe cities.

- Sports analysis.

We will endeavour to cover each Industry application use case in details in subsequent features. Today we will focus on how VisionBot™ driven automated reporting and exceptional alerting helps construction companies become more safe, efficient and profitable.

Ai Driven Automated Visual Inspection Monitoring for Construction Industry

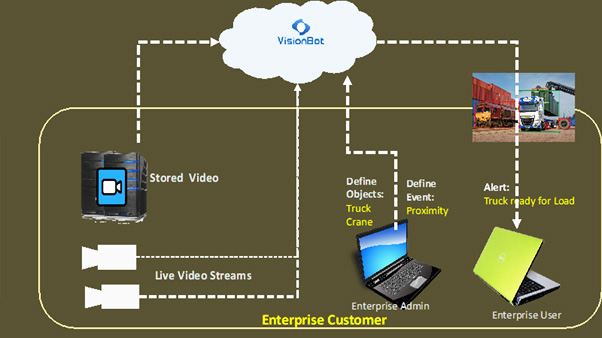

VisionBot™ is a platform that leverages the scalability and availability of cloud services to offer its Augmented Computer Vision based solutions. VisionBot™ helps businesses get the most out of their visual content, thereby deriving powerful insights and driving decision making. Designed as a cloud based Software-as-Service (SaaS) model, it lets any customer start using the system with minimal investment. VisionBot™ is offered as an on-premise service in Hybrid/ Private Cloud/ Data Centre for enterprise requirements. It is an adaptive platform and learns on its own, to deliver required outcomes depending on enterprise use cases.

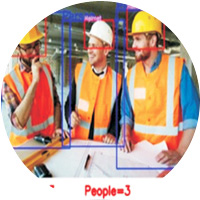

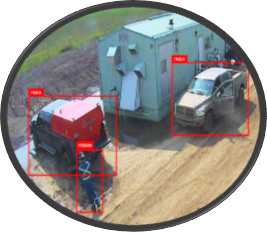

There are several use cases of Visual Monitoring for the Construction sector. With its wide stretch of land and real estate variety of vehicles and equipment and large number of workers and supervisors, visual monitoring of assets and human resources helps address both occupational safety and operational efficiency.

Therefore construction sector has several use cases where Automated Visual Monitoring is a compelling need. Visionbot™ helps automating several functions in construction that are tedious/ dangerous for humans or erroneous under human monitoring.

We use advanced AI and machine learning tools to train an algorithm to distinguish different things in an image and automatically report on anomalies. Turn images into information to provide real-time detection of events, things of importance and anomalies on the site. This information can be used to better assess productivity, security, risks and hazards.

It is also a cost-efficient option where there is a need for large manpower:

- Workplace safety and compliance.

- Inventory management.

- Routine and special inspections.

- Attendance and access control.

- Theft protection & vandalism.

- EHS & EPC safety monitoring.

- Project monitoring.

1. Compliance to Wearing Helmets at Sites

This is a task which is difficult to achieve through human supervision alone. Visionbot™ can use cameras installed at the entrance as well as several critical spots to continuously keep monitoring the labourers and report on those who are not wearing helmets.

2. Compliance to Workplace Safety

Mandatory compliances to wear industrial grade safety boots at hazardous spots.

3. Automating Attendance and Access Control

VisionBot™ can potentially be used to record attendance of employees and contract staff.

4. Counting of Manifests/ Material

In a general business sense, construction work involves inventory management of a number of costly items. VisionBot™ can continuously watch over the storage and movement of costly items at the construction sites.

5. Assisting with other Visual Inspections

Critical moving equipment such as pumps require daily visual inspection. These are routine manual tasks with no trail or records, thereby fixing the responsibility at a later point of time is impossible whereas violations will result in huge penalties and insurance costs. These can be automated and done continuously with tracking and recording using VisionBot™.

![]()