Automated Visual Inspection & Content Analysis for Manufacturing – Automotive

Prakash Prabhu – Chief Business Officer & Co-Founder, VisionBot

In this feature, we will discover benefits of automated visual inspection, content analysis and deep learning methodologies for Manufacturing enterprises.

Computer vision driven automated video content monitoring for future digital factories

Manufacturing. Image: Open Source

Computer vision can be used in manufacturing for quality assurance by automatically inspecting products for defects or deviations from specifications. This can be done using techniques such as image processing and deep learning to analyse images or videos of the products.

Computer vision is a type of technology that is revolutionizing the way that we think about retail. By using machine learning algorithms, computer vision is able to ‘see’ the world around us and make sense of it in ways that were previously impossible.

Computer vision can be used in manufacturing for quality assurance by automatically inspecting products for defects or deviations from specifications. This can be done using techniques such as image processing and machine learning to analyse images or videos of the products. This can help to improve the accuracy and efficiency of the inspection process and reduce the need for human inspection. Some examples of computer vision application in manufacturing include:

Identifying defects on a surface of a product

Computer vision can be used to identify defects on a product surface by using techniques such as image processing, pattern recognition, and machine learning. This can be done by capturing an image of the product surface, pre-processing the image to remove noise and improve contrast, then using algorithms to detect any anomalies or defects that deviate from a standard pattern. Some common defects that can be detected include scratches, cracks, chips, and blemishes. The results can be used for quality control and to improve the manufacturing process.

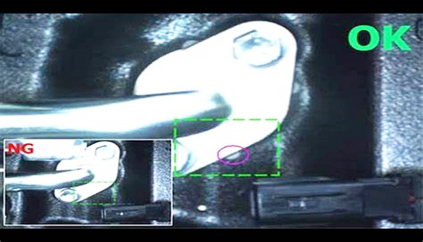

Checking the alignment and orientation of components

Computer vision can be used to check the alignment and orientation of components by using image processing and computer vision algorithms. This can be done by capturing an image of the components and using algorithms to analyse the image and determine the relative positions and orientations of the components. Some common algorithms used for this include feature detection, template matching, and edge detection. The results can be used for quality control and to improve the manufacturing process by ensuring that components are properly aligned and oriented. This can help to reduce defects and improve product reliability.

Measuring dimensions and tolerances

Computer vision can be used for measuring dimensions and tolerances by analyzing images of objects and using algorithms to extract dimensional information. This can be done using techniques such as edge detection, blob analysis, and pattern recognition. The system can be calibrated using a known reference object, and then used to measure the dimensions and tolerances of other objects. The results can be used for quality control, to ensure that products meet specified dimensional requirements, and for process improvement, by using the data to optimize production processes. The use of computer vision in measuring dimensions and tolerances can increase accuracy and efficiency compared to manual measurements.

Detecting missing or misplaced parts

Computer vision can be used to detect missing or misplaced parts by analysing images of a complete assembly and comparing it to a reference image of the expected assembly. This can be done using image processing techniques such as object detection, pattern recognition, and machine learning. The system can be trained on a set of images to learn what a complete assembly should look like, and then use this knowledge to identify any missing or misplaced parts in new images. The results can be used for quality control, to ensure that all necessary parts are present and properly assembled, and for process improvement, by using the data to optimize production processes. The use of computer vision in detecting missing or misplaced parts can increase accuracy and efficiency compared to manual inspection.

Monitoring assembly processes for compliance with standard procedures

Computer vision can be used to monitor assembly processes for compliance with standard procedures. This is done by using cameras to capture images and videos of the assembly process, and then using computer vision algorithms to analyse the images and videos in real-time. These algorithms can be used to detect deviations from standard procedures, such as incorrect assembly sequence or incorrect parts being used. This information can then be used to alert operators to take corrective action or to record non-compliant actions for further analysis and improvement of the process.

Tracking and identifying products throughout the manufacturing process

Computer vision can be used for tracking and identifying products throughout the manufacturing process. This is done by using cameras to capture images and videos of the products at various stages of the manufacturing process, and then using computer vision algorithms to analyse the images and videos in real-time. These algorithms can be used to identify individual products and track them as they move through the manufacturing process. This information can then be used to ensure that each product is processed correctly, and to track the location of products within the manufacturing facility. Additionally, computer vision can also be used to verify product quality, by analysing images of each product to ensure that it meets specified quality standards.

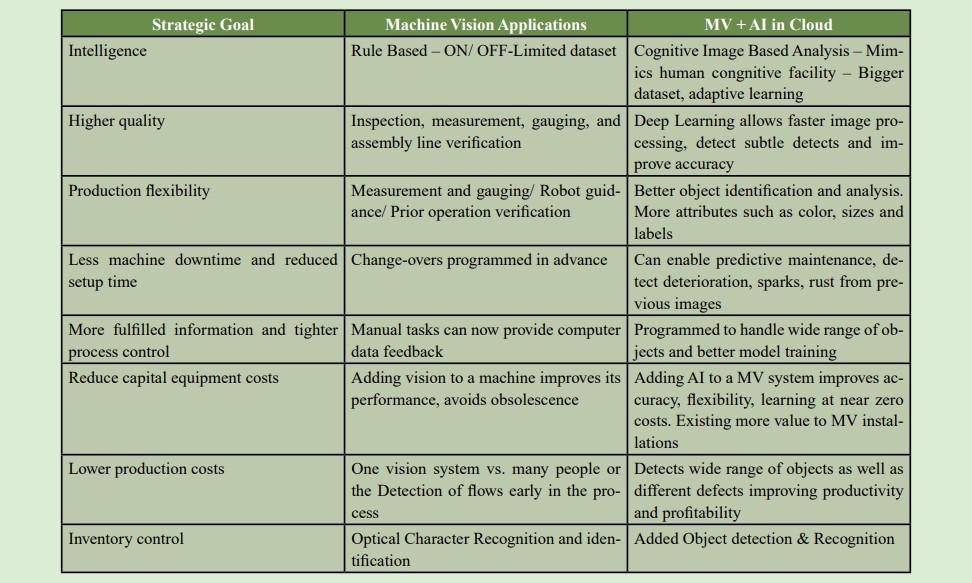

Integrating Machine Vision with AI driven Augmented Computer Vision

Objective of the integrated solution – To use automated visual monitoring and AI driven event notifications to monitor, detect and alert for real time observations, asset monitoring, predictive maintenance and centralized reporting of Visual monitoring and Machine Vision Images, alerts on incident/ event detection.

VisionBot™ Cloud Automated Computer Vision for Automotive Manufacturing

VisionBot™ Computer Vision is one of the many Artificial Intelligence solutions that will continue to transform manufacturing. Leading survey says computer vision will be very important, and 58% said that their firm is implementing, planning to implement, or interested in implementing computer vision in the coming year.

It allows machines to extract meaningful information from image and, now, even video data by using sophisticated machine learning models. Imagine a world where anything the human eye can see and brain can process, a computer can. Now go beyond that, as Computer Vision can reach past the natural human vision spectrum.

Traditional object recognition identifies a frame in 2D, and can identify a photo of a man standing next to an engine. There are many different computer vision techniques ranging from image classification, which involves classifying images into predefined categories based on the actual content of the image to video analytics, which applies computer vision and spatio-temporal analyses to automatically identify significant information contained in video streams (a series of images or pixels), including the ability for human activity and posture to be detected and classified as different motions.

Applications Include:

- Assembly Automation.

- Predictive Maintenance.

- Reducing Workplace incidents.

- Quality assurance on the production line.

- Inventory – Finished and WIP.

- Industrial Safety – Compliance & workplace security.

- Vehicle Insurance.

VisionBot™ learns the characteristics of a product directly from the production line and automatically assesses its quality. This device is very simple to use and does not require complicated programming procedures by experts; therefore, easily, it is ready to control new products with different characteristics quickly.

Any traditional machine vision system can analyse complex objects or products with high variability as easy as a human operator would. While, VisionBot™, on the other hand, interprets the concept of ‘quality’ as fast as most trained control operators. VisionBot™ can be customized according to the production requirements of the moment since its ‘severity’ level can be increased or decreased at the touch of a button, thus loosening or tightening the product acceptance criteria.

At any time and with a simple click, VisionBot™ can learn how to sort a new product or adapt to changing production conditions, and it chooses automatically, which will be the features to monitor that best describes the quality of your products.

AI cloud solutions can bring state-of-the-art deep learning to solve industrial computer vision problems, utilising the innovative AI methods built on top of the modern cloud technology stack.

Connect with our experts to understand how companies are using Augmented Computer Vision to strengthen security, safety and streamline operations.

Become a VisionBot™ channel partner, and discover the opportunity to offer a cutting-edge AI-powered computer vision solution to your customers at ZERO CAPEX, generate new revenue streams, and benefit from the expertise and support of the VisionBot™ team.

https://visionbot.com/partnering

We will cover VisionBot™ Partner Program and its advantages soon

*Views expressed in the article are solely of the Author