Prakash Prabhu

Chief Business Officer & Co-Founder, VisionBot

As we enter the year 2024, the world of logistics is poised for transformation. The logistics industry ,a vital backbone of global trade and commerce, is constantly changing in response to technological advancements, changing consumer behaviors, and business concerns. Logistics is moving forward in every aspect, and one of the clearest logistics trends for 2024 is digitalization.

Artificial intelligence (AI) in the supply chain will also be fundamental in 2024. This is mainly due to the immense amount of structured and unstructured data that exists in this area. AI technologies here such as machine learning, and predictive analytics that hold a huge potential to add value in terms of providing real-time data insights, improving operational efficiencies, and enabling data-led decision-making.

The refinement of Visual AI will simplify access to internal and external information, with the expansion of AI, automation and real-time visibility as go-to strategies. According to Gartner’s forecasts, by 2026, more than 80% of companies will have used AI-driven applications in production environments compared to the current 5%.

Logistics companies need to harness the power of automation in 2024 by implementing end-to-end integrations, as businesses continue to incorporate more platforms and systems into their processes, data becomes more abundant and valuable. The fast and efficient delivery of products from the warehouses to the door steps of the customers, is achieved through thoughtful warehousing and logistics management system.

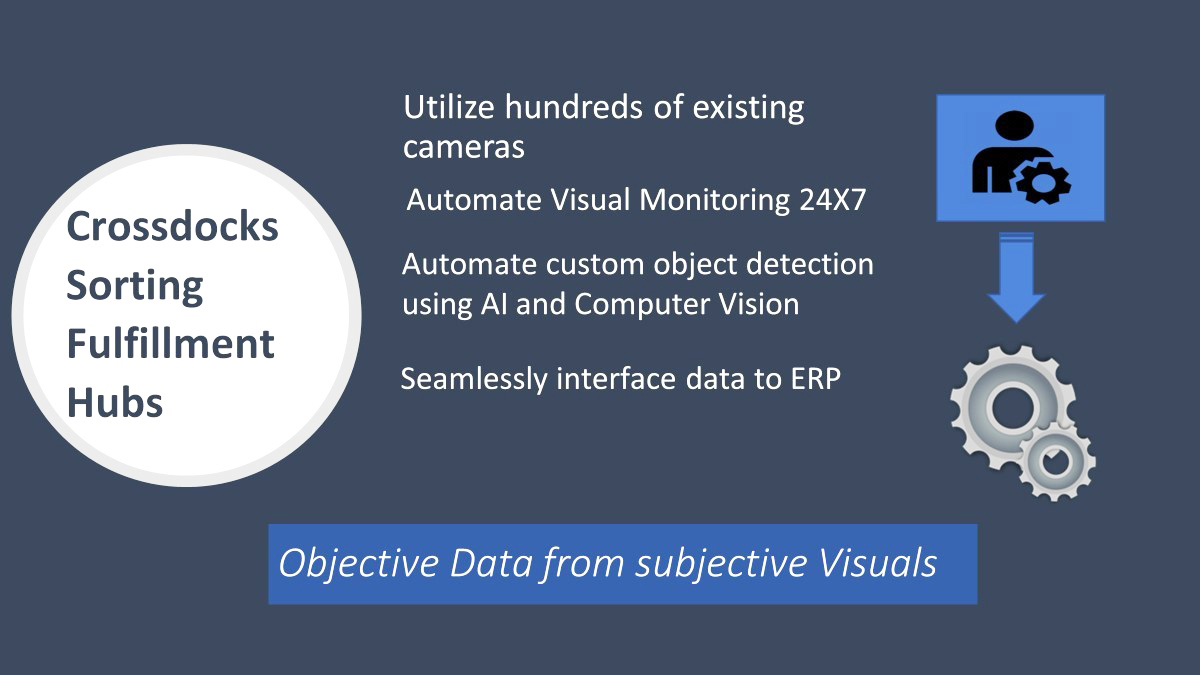

Effective Logistics needs intricate a distribution network comprising of different types of facilities, which play a crucial role in its supply chain and needs building efficiencies across multiple processes to boost productivity and process compliances.

- Crossdock centers: Shipment from vendors are stored here until more inventories are required by the fulfillment center.

- Fulfilment centers: The packages are stored here before being picked up for delivery.

- Sortation centers: In this facility the products are sorted by respective delivery addresses (zip codes) before they are sent out for delivery.

- livery stations: The delivery stations are meant to improve last mile delivery.

- Local hubs: These facilities enable time sensitive deliveries such as groceries, which need to be delivered in a matter of hours.

Which are the areas that Visual AI can contribute to productivity?

- Warehouse optimization.

- Damaged cargo detection.

- Package identification.

- Package counting.

- Empty space – utilization.

- Real-time inventory visibility.

Some of the processes that can be optimized using Visual AI

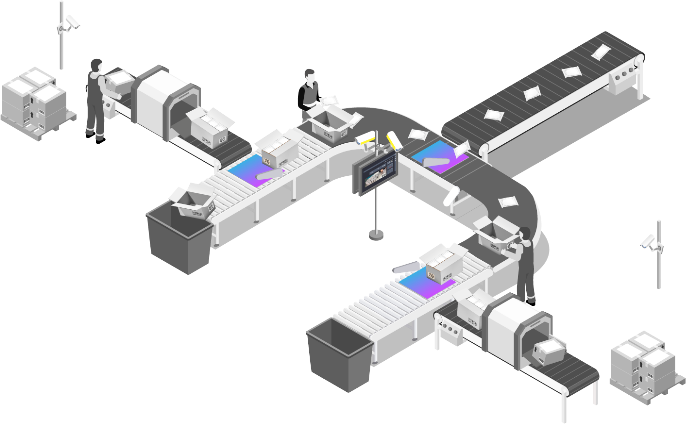

solutions are Traceability and tracking of objects: Smart tracing applications aim to identify and localize logistics objects such as goods, containers, vehicles, or persons within logistics systems. It can be achieved by attaching optical codes to objects such as barcodes or QR-codes and using image processing algorithms to capture and read the optical codes.

Vision-based good identification: Such identification systems are widely popular to identify incoming and outgoing goods in warehouses and distribution centers. In port logistics applications, OCR systems are used to read container codes and license plates (ANPR) of trucks and delivery vans in real-time.

Container number recognition: System Computer vision has been used to recognize container numbers automatically. Number recognition is used to automatically detect and locate containers in large-scale areas. Regular security cameras provide a visual image that is pre-processed and fed into an ML model. With modern convolutional neural networks (CNN), logistics objects can be identified and localized even without optical codes.

Volumetric properties of goods: In logistics processes, the volumetric properties of goods are critical for planning and billing quantities. Its automation enables significant time savings and optimization of operational efficiency. Hence, vision-based systems to detect dimensions of goods are widely popular to detect parcel dimensions on conveyor systems.

Goods and pallet dimensioning: Standard surveillance cameras are also suitable for dimensioning palletized goods and packages, provided the systems are calibrated using specific reference points. Inspection and quality control of goods Computer Vision in logistics has many use cases to ensure the quality of goods throughout the supply chain.

Equipment condition monitoring: Equipment condition inspection and monitoring AI vision systems are widely used for conditions monitoring of logistics equipment.

Early defect detection: In another application, Visual AI can provide images to detect defects in conveyer systems resulting from high friction. Moreover, existing cameras are used for condition inspection on belt conveyors to early detect belt displacements.

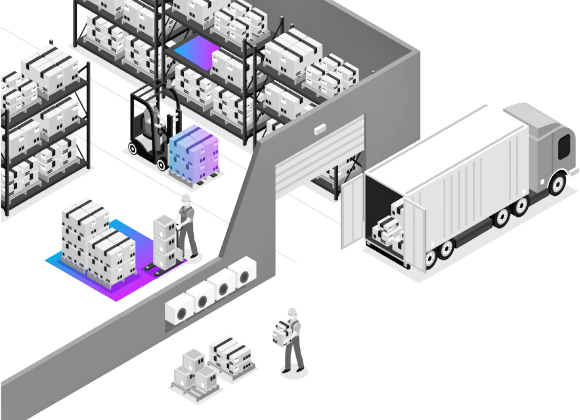

Determine free capacity of transport vehicles: Camera-based approaches have been implemented to determine the free capacity of transport vehicles, for example, with cameras oriented toward trailer gates. The current loading conditions and space allow optimizing the operating costs and efficiency.

Docks and parking lot occupancy detection: Computer vision technology can support yard and dock management by monitoring the occupancy of docks or parking lots. The loading states of forklifts are of interest to determine the coordinates of delivered goods in warehouses. Parking lot occupancy detection for computer vision in logistics

Storage bin occupancy analysis: This approach can be easily applied to other domains, for example, to detect free storage bins in warehouses. The occupancy of storage bins is used to detect critical process situations and to optimize transport routes.

Security and protection of facilities: Infrastructure and logistics facilities are the basis for logistics processes. Therefore, it is of great importance to protect them against internal or external hazards such as accidents, theft, terror attacks, and others.

Intrusion detection in logistics facilities: AI video surveillance is a widely popular, effective solution to increase security in logistics facilities such as warehouses. Modern deep learning methods allow intrusion detection with virtual fences to identify dangerous situations automatically. Related security applications include vehicle detection in restricted areas or large-scale face recognition. Intrusion detection in logistics with deep learning

Crowd detection and behavior analysis: Innovative systems include camera-based systems for people counting, crowd density estimation, and crowd behavior analysis to increase security at logistics facilities. People counting application with deep learning Due to legal requirements, privacy features are becoming increasingly important. Edge AI based vision systems allow private on-device processing in real-time, with only sending analytics data to the cloud.

Vision-based Anomaly detection: With anomaly detection using machine learning, critical situations can be predicted to initiate preventive measures.

Process modeling and simulation: For planning and predicting the performance of logistics systems, simulation methods are of great importance. Image recognition systems are helpful in collecting process data for close-to-reality simulation.

Data collection for process analysis and optimization: With object detection and object tracking, material flow parameters such as number, state, flow directions, throughput, and throughput time can be calculated. These parameters can be used for simulation-based optimization and evaluation of logistics processes.

Optimize manual picking and sorting: While there is a significant trend towards automation in logistics, the share of manual work in handling processes is still substantial. This is because of the diversity of goods which makes automation very challenging.

Wrong placing detection with cameras: Since manual work is very error-prone, vision systems help to assist in picking and packing operations to reduce the error rates and save costs. Visual AI systems help determine whether objects are placed correctly into a container and provide visual feed-back about the handling process to indicate detected errors.

Human error detection with deep learning: Sophisticated vision systems use hand movement estimation with deep learning to detect whether the correct goods were packed. Other applications recognize objects inside a package and compare them to order lists. The use of deep learning allows new applications in logistics operations related to picking, packing, and placing, with many applications also being applied in warehouses.

Automated material handling systems involve handling, loading, picking, and sorting operations along the supply chain. Here, modern image recognition supports this automation.

As a leading Visual AI Company, VisionBot helps to leverage the latest in computer vision technology to help businesses and organizations automate processes, improve customer experiences, and gain valuable insights in to their operations.

*Views expressed in the article are solely of the Author