Prakash Prabhu – Chief Business Officer & Co-Founder, VisionBot

In latest rapid-paced production and first-class manipulate environments, precision and performance are paramount. Ensuring product first-class while optimizing manufacturing tactics is a steady project. This is wherein Automated Visual Inspection (AVI) structures come into play. AVI structures leverage modern era, including artificial intelligence and system mastering, to carry out visual inspections with incredible accuracy and velocity. However, implementing such systems involves an economic investment. To decide whether it is a profitable undertaking, groups frequently behaviour a Cost-Benefit Analysis (CBA). In this write up, we’ll explore the idea of CBA in the context of AVI systems, inspecting the way to examine the Return on Investment (RoI) when imposing these technologies

Understanding Automated Visual Inspection Systems

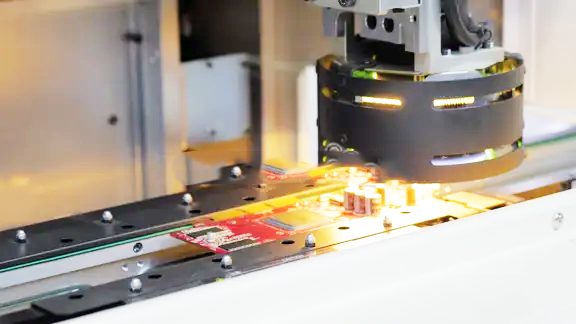

Automated Visual Inspection systems are designed to duplicate and often exceed the talents of human vision. They use cameras, sensors, and superior algorithms to research and evaluate products, additives, or substances for defects, inconsistencies, or first-rate deviations. AVI systems can be deployed in various industries, inclusive of manufacturing, electronics, prescribed drugs, automobile, and food manufacturing, to name some.

Here’s how they normally paintings:

- Capture Images or Video: AVI structures use cameras to capture snap shots or films of the gadgets being inspected.

- Processing and Analysis: These images or motion pictures are processed by specialized software program that employs artificial intelligence and de vice mastering algorithms. This software program can become aware of defects, degree dimensions, verify product integrity, and more.

- Decision-Making: Based at the analysis, the machine makes selections in actual-time. It can categorize objects as ‘bypass’ or ‘fail,’ triggers alarms or signals while defects are detected, and even initiates corrective actions in some cases.

- Data Logging and Reporting: AVI systems frequently log inspection facts and generate special reports. This information can be helpful for exceptional manipulate, method development, and compliance functions.

The Need for Cost-Benefit Analysis

The integration of AVI systems into current processes requires a large investment in terms of hardware, software, training, and integration. Therefore, enterprises must determine if the advantages will exceed the expenses before making such a significant investment. The Cost-Benefit Analysis (CBA) is useful in this situation.

Cost-Benefit Analysis (CBA) for AVI Systems

The financial viability of a project or investment is assessed using the cost-benefit analysis method, which is an organized procedure. CBA entails a complete analysis of the advantages and disadvantages of adopting Automated Visual Inspection systems in the context of deploying them.

Here is the normal procedure:

Identifying Costs:

- Initial Investment: This consists of the value of purchasing AVI hardware, software licenses, and any extra system or infrastructure required for implementation.

- Installation and Integration: Expenses associated with the setup, configuration, and integration of AVI structures into current manufacturing traces or tactics.

- Training: Costs related to training personnel to perform, hold, and troubleshoot the AVI machine efficiently.

- Operational Costs: Ongoing fees inclusive of preservation, software updates, and any required technical aid or carrier agreements.

Identifying Benefits:

- Quality Improvement: AVI structures are frequently carried out to decorate product exceptional. This gain can be hard to quantify but could have a massive impact on purchaser satisfaction and popularity.

- Reduced Labor Costs: Automated Visual Inspection systems can extensively lessen the want for manual inspections, saving on exertions charges.

- Increased Throughput: By carrying out inspections at excessive speeds, AVI systems can contribute to expanded production performance.

- Reduced Scrap and Rework: Detecting defects early in the production process can lessen scrap and rework costs.

- Compliance and Risk Mitigation: AVI systems can also assist in ensuring adherence to enterprise norms and policies, reducing the hazard of high-priced penalties or product recollects.

- Data-Driven Insights: The statistics accrued via AVI structures can provide valuable insights for manner optimization and continuous improvement efforts.

Steps to Perform a CBA for Automated Visual Inspection Systems

Performing a CBA for AVI systems includes a hooked up method to evaluate the costs and advantages. Here are the key steps:

1.Define the Scope

Clearly outline the scope of the AVI implementation challenge. Identify the right merchandise or strategies to be able to reduce hassle to the computerized inspection.

2.Identify Costs

- Initial Investment: Calculate the entire fee of acquiring and putting in place the AVI device, which include hardware, software program software program, and set up.

- Training Costs: Estimate the charges associated with training employees to feature and hold the AVI device.

- Operational Costs: Determine ongoing prices, which encompass maintenance, software, software updates, and technical assists.

3.Identify Benefits

- Quality Improvement: Assess the potential effect of AVI on product brilliant and consumer delight. Consider factors collectively with reduced defects and superior consistency.

- Labor Cost Reduction: Estimate the tough work price economic financial savings as a result of the decreased want for guide inspections.

- Increased Throughput: Calculate the capability growth in manufacturing output because of quicker inspections.

- Scrap and Rework Reduction: Estimate the price economic savings from minimizing scrap and remodel.

- Compliance and Risk Mitigation: Consider the potential value financial savings from averting fines or recalls due to non-compliance.

- Data-Driven Insights: Determine how to use the data gathered by AVI systems to enhance the system and reduce costs.

4.Calculate the Net Benefit

Subtract the entire expenses (initial funding, schooling, and operational expenses) from the entire blessings (excellent improvement, exertions cost discount, throughput boom, scrap and remodel cut price, compliance benefits, and information-pushed insights).

5.Calculate the RoI

Calculate the Return on Investment (RoI) by dividing the net benefit by the total costs and expressing it as a percentage. RoI = TotalCosts/ NetBenefit×one hundred.

6.Sensitivity Analysis

Perform sensitivity analysis to assess how changes in key variables, including inspection speed or hard work fee financial savings, effect the RoI. This enables in expertise the robustness of the investment choice.

7.Decision-Making

Based at the calculated RoI and sensitivity analysis, make a knowledgeable choice about whether or not to proceed with the implementation of the AVI gadget. A positive RoI shows that the funding is financially justified.

Factors Affecting RoI for Automated Visual Inspection systems

Several factors can impact the ROI of implementing AVI structures:

1.Scale of Implementation

The length and complexity of the AVI gadget deployment can notably affect each expenses and blessings. Larger-scale implementations can also yield better advantages however also incur better initial costs.

2.Inspection Speed

The pace at which the AVI machine can look at merchandise is crucial, specifically in high-volume manufacturing environments. Faster inspection can lead to expanded throughput and cost financial savings.

3.Labor Costs

The extent to which AVI structures reduce the need for manual inspections depends on labor fees. Higher hard work charges can bring about more significant value financial savings.

4.Quality Improvement

The amount to which AVI systems enhance product pleasant and decrease defects may want to have a widespread impact on RoI. Improved best can purpose customer retention and loyalty.

5.Industry and Regulatory Compliance

The blessings of Automated Visual Inspection systems in making sure compliance and lowering risk may be widely felt in sectors with strict standards for fine and compliance.

Conclusion

Companies might also additionally advantage substantially from automated seen inspection structures such as improved product high-quality, decrease hard artwork fees, increased throughput, and risk cut price. However, imposing these systems involves preliminary investments in hardware, software application software software , education, and integration. To verify the financial feasibility of implementing Automated Visual Inspection systems, organizations should behaviour Cost-Benefit Analysis (CBA) and calculate the Return on Investment (RoI).

A wonderful RoI indicates that the funding in AVI systems is financially justified and can reason big fee monetary financial savings, first rate upgrades, and aggressive advantages. However, the precise RoI of AVI systems can variety primarily based mostly on elements together with scale, inspection tempo, difficult paintings charges, tremendous improvement, and commercial enterprise employer compliance necessities. It’s critical for companies to cautiously examine those factors and carry out an extensive CBA to make informed investment options that align with their strategic dreams and financial dreams.

*View expressed in the article are solely of the Author